About Wonderware MES/Quality, Intelligence, InBatch, Mobile Solutions and Wonderware Workflow featuring guest writers & partners

Friday, January 31, 2014

Fun with Wordle: Wonderware InBatch

Need enterprise-strength recipe management? A product that conforms to industry standard ISA-88 for batch recipe management and execution? Consider Wonderware InBatch. It's flexible, used by the leaders in the pharmaceutical, chemical, and food and beverage industries for its robustness, model-driven approach, integrated workflow, and more.

Manufacturing Execution Systems Deliver Real Value and Competitiveness

Customer References verified by TechValidate.

by Michael Schwarz, MES/EMI/Workflow Product Manager, Invensys Schneider Electric

Every manufacturer

approaching the transformation from a paper based, fragmented or manual operations

management system to a Manufacturing Execution System (MES) raises that

question – what will be the ROI (Return on Investment) in my case? Often this question cannot be

exactly answered directly – only very experienced professionals will be able to compare

a prospect's situation to a similar case, and relate to the results achieved in

these case(s) without detailed analyses and investigations which may require

similar efforts close to a small MES implementation itself!

We wanted to know

better ourselves and asked our existing Wonderware MES Software customers what

operational improvements and ROI they achieved, to share with those who need

decision support to justify the investment. We partnered with a research

service, TechValidate, to collect and validate such information for publication. The chart above is an overview of Improvements

through Wonderware MES Software use.

Fun with Wordle: Wonderware Information Server

How can you view your Historian data easily, interactively, and with detail? Using Wonderware Information Server. Wonderware Information Server aggregates and presents plant performance metrics and production data to operations, maintenance and engineering personnel, via an easy to implement web solution.

It can host other Wonderware applications, such as Wonderware Intelligence and Wonderware MES. It's part of our productivity suite, and you should consider it for ongoing information management and reporting.

Thursday, January 30, 2014

Wondeware's IntelaTrac Drives Efficiencies at Infineum

IntelaTrac is the industry-leading mobile workforce and decision support system. Companies in the oil and gas, food and beverage, chemicals, power, and other industries depend on IntelaTrac for monitoring, guiding, and informing field workers, bringing more efficiency and accuracy to maintenance and task management.

Infineum has used IntelaTrac for years to manage their equipment maintenance. To read the full Success Story, click here

Wednesday, January 29, 2014

Repost, with comments: Invensys' MOM Software Capabilities as Part of Schneider Electric

http://blog.lnsresearch.com/blog/bid/192361/invensys-mom-software-capabilities-as-part-of-schneider-electric?source=Blog_Email_[Invensys%27%20MOM%20Softwa]

Mark Davidson of LNS Research just posted a very fair and measured analysis of Invensys' Manufacturing Operations Management (MOM) software capabilities, capping his discussion with an overview of the Schneider Electric acquisition of Invensys.

Over the past 10 years, Invensys has steadily increased their focus and investment on the needs of the manufacturing and infrastructure industries, providing full-scope solutions for visibility, reporting and analysis, and process control. The addition of plant floor control systems from Schneider Electric will offer more choices for customers to fill in the gaps in their solution set, add capabilities and set the path for future improvements.

Mark Davidson of LNS Research just posted a very fair and measured analysis of Invensys' Manufacturing Operations Management (MOM) software capabilities, capping his discussion with an overview of the Schneider Electric acquisition of Invensys.

Over the past 10 years, Invensys has steadily increased their focus and investment on the needs of the manufacturing and infrastructure industries, providing full-scope solutions for visibility, reporting and analysis, and process control. The addition of plant floor control systems from Schneider Electric will offer more choices for customers to fill in the gaps in their solution set, add capabilities and set the path for future improvements.

Tuesday, January 28, 2014

Microsoft Global Energy Forum 2014 – February 20, 2014

Join Invensys

at the George R Brown Convention Center

in downtown Houston, Texas for this spectacular event!

Stop by

the Invensys booth

and speak with our Invensys energy experts to match the solutions to your

requirements and to help achieve sustainable results at the Microsoft Global Energy Forum 2014 at the

George R Brown Convention Center on Thursday, February 20th, 2014!

Through

our Wonderware

portfolio solutions, we provide manufacturers with real-time visibility into

their plant environments and supply chains. Based on Microsoft technology our

Wonderware solutions are implemented in a variety of industries, including

Hydrocarbon Processing, Power, Food & Beverage, Metals, Minerals &

Mining, Water/ Wastewater, and Upstream Oil & Gas.

Meet

with our Invensys experts to uncover the best Wonderware solution for your

energy requirements:

•

Real-time “energy management” – discover wasteful energy situations, saving

money

• Real-time energy and financial measurement

• Real-time intelligence and empowerment

• Real-time energy conversion and distribution control

• Real-time energy optimization

• Lifecycle solution services

• Real-time energy and financial measurement

• Real-time intelligence and empowerment

• Real-time energy conversion and distribution control

• Real-time energy optimization

• Lifecycle solution services

The

Global Energy Forum is a prestigious annual technology-focused energy industry

event welcoming business leaders in both Business Operations and Information

Technology roles.

News Release: Invensys Selected as "First Team" Supplier by readers of Automation World!

News Release

Invensys is honored to be selected as a "First Team" supplier of products such as Manufacturing Execution Systems, Information Management Systems, and HMI/SCADA Systems. It is a testimony to the effort and vision of making our customers more successful by providing solutions that make them more cost effective, energy efficient, and productive. Thank you to the readers!

Invensys is honored to be selected as a "First Team" supplier of products such as Manufacturing Execution Systems, Information Management Systems, and HMI/SCADA Systems. It is a testimony to the effort and vision of making our customers more successful by providing solutions that make them more cost effective, energy efficient, and productive. Thank you to the readers!

Thursday, January 23, 2014

Adding a Wonderware Historian provides greater insight into your process...

Why would you want to use Wonderware Historian if you are a Wonderware InTouch HMI customer? Let me count the ways! Better performance, better process visibility, better, indepth reporting capabilities, and more.

Eskom Centralizes Critical Power Generation Data using Wonderware Information & Reporting Solutions

Eskom Holdings, based out of South Africa, wanted to standardize their visualization and control software on a single platform to ensure all plants had a common tool for operations management. Consistent demand and supply is critical to power companies, and Eskom turned to Wonderware in order to accomplish their foundation.

A complete success story is available here.

Don’t miss an opportunity to attend Avantis Training in February/March 2014!

The Avantis® advanced Enterprise Asset

Management (EAM) Suite enables your enterprise to do more than simply maintain its assets. It is designed to meet the sophisticated maintenance and materials

management requirements of today’s asset-centric organizations.

To support real-time plant operations, Avantis is fully and seamlessly integrated with Distributed Control Systems (DCS's) and Programmable Logic Controllers (PLC's) on the

plant floor; and it incorporates and responds to predictive condition

monitoring processes.

All upcoming courses are

being held in our Burlington, Ontario, Canada location.

Below is a snapshot of course availability:

Below is a snapshot of course availability:

Wednesday, January 22, 2014

Wonderware MES Customer Success: Baltika Beverages Case Study, Validated by TechValidate

Customer Evidence verified by TechValidate.

For manufacturers in the food and beverage industry, good manufacturing practices, brand protection and process tuning are critical for profitable and sustainable operations.

Wonderware MES customer Baltika is no exception. Equipment uptime, product quality and line availability are paramount to respond to their customer demand and maintain an effective supply chain. They were able to improve OEE (Overall Equipment Effectiveness) by over 10% using Manufacturing Execution Solutions from Wonderware, driving profits to their bottom line. Enterprise integration, from their automation systems to their business systems, helped to manage work orders, enable timely shipping and material consumption information back to their ERP. Other benefits included paperless work order execution, as well as supporting Food Safety initiatives via indepth product track, trace and genealogy.

Fun with #Wordle: Avantis.DSS

Another #Wordle word art. Avantis.DSS is Decision Support Software that combines a scorecard, Key Performance Indicator Dashboard, and Reporting into a single unified tool set. Built on the rigor of #Avantis, it reflects years of experience in maintenance and materials management best practices.

Avantis.DSS enables you to do more than just track your past activities--it provides you with insight to make informed business decisions to effectively manage all of your assets with confidence. For more information on Avantis.DSS, please click here.

Tuesday, January 21, 2014

Fun with Wordle: Schneider Acquisition of Invensys

thanks to my colleague +Bill Schiel for suggesting! As you may have read, Schneider Electric recently completed their acquisition of Invensys. It's a great time for industry to have more, broader choices.

thanks to my colleague +Bill Schiel for suggesting! As you may have read, Schneider Electric recently completed their acquisition of Invensys. It's a great time for industry to have more, broader choices.

MESA International's GEP Competency Class: A Reference from an Attendee

You may know that MESA International offers a Global Education Program (GEP) to further industry knowledge and competence. MESA is accredited as an Authorized Provider by the International Association for Continuing Education and Training (IACET), so attending these classes provides you with continuing education units.

I wanted to share with you a recent experience from one of our senior consultants:

"I

recently attended and was awarded the MESA GEP Certificate of Competency.

I attended the class in attempts to better round out my knowledge of the

various topics related to Manufacturing Operations Management, particularly the

ties to ISA-95. I was not disappointed!! The course offered a

variety of relevant segments that addressed the different aspects of Operations

Management including strategy development, project justification approaches and

a review of various technology options. I would recommend this for anyone

determined to successfully tackle an operations management and integration

program. It was well worth the time!!" Kevin Fitzgerald, Invensys North America Consulting Group.

So isn't it time that you invested in your career? Consider the MESA Global Education Program for focused training conducted by instructors with decades of experience in automation and operations management solutions. It's well worth it!

Monday, January 20, 2014

The State of Manufacturing: I'm Optimistic for 2014!

Last year, I published a post on the state of manufacturing, and how I thought that recovery was imminent. I am not a fortune teller and I certainly am not an economist, but you get a feeling based upon sales confidence levels, deals, and industry chat whether it's going to be a good year, or a down year. Well, like last year, I think it's going to be a good year. Not just for Invensys (becoming a Schneider Electric Company) but because as a whole there appears to be a palpable positive attitude from the industry as a whole. Let's look at some proof points.

Sunday, January 19, 2014

Announcing the Release of Avantis.PRO 5.0.5

by Audra Reddy, Product Marketing, Asset Management, Invensys

Avantis.PRO version 5.0.5 has now been released! Here is a quick overview of version 5.0.5:

Technical Support: As always, feel free to reach out to your local technical support team for more information.

Avantis.PRO version 5.0.5 has now been released! Here is a quick overview of version 5.0.5:

- Lockout/Tagout functionality for supporting

safe plant operations

- Italian and Russian localization

- Customer-driven Operational improvements, including overtime enhancement, security enhancement, Work Task Enhancement and Performance Enhancement

About Avantis.PRO: Avantis.PRO is an

asset performance management solution designed to meet the sophisticated

maintenance management requirements of today's asset-centric organizations.

Today's global competitive stakes make it more important than ever to implement

maintenance strategies that are linked to the company's overall business plan.

Avantis.PRO Asset Performance Management software enables you to organize,

track and understand your asset utilization, performance, and availability.

Technical Support: As always, feel free to reach out to your local technical support team for more information.

Saturday, January 18, 2014

Maintenance Practices Enable Sustainability

by Curtis Wilson

People are thinking green. Companies that integrate sustainability into their products, services and operations are well-positioned to shine.

Avantis Principal Asset

Management Consultant, Schneider Electric (Invensys)

People are thinking green. Companies that integrate sustainability into their products, services and operations are well-positioned to shine.

No matter how sustainable a group of assets may have been in

the original design and construction, they must be operated responsibly and maintained

properly to continue to function as designed. Therefore, the core ideology of

sustainability and maintenance are directly linked.

Since sustain and maintain are very similar from a definition

point of view, it only makes sense that Sustainability and Maintenance should

be closely linked. A company that strives toward World Class Sustainability

needs to have World Class Maintenance practices and technology.

Organizations that established enterprise-wide preventive and

predictive maintenance programs find that maintenance costs can be reduced by >40%

and energy consumption by >10%. Properly maintained equipment also produces

less waste and environmental impact. Safety is dramatically increased when

equipment is properly maintained because it improves employee morale and public

perception of the organization.

Companies that are good corporate citizens are sustainable

for the benefits achieved in all three circles of the Triple Bottom Line.

Energy conservation is critical to sustainability because it heavily impacts

all three areas of the Triple Bottom Line. Many people outside of the

maintenance function fail to recognize that performing world-class preventive

maintenance (PM) and predictive maintenance (PdM) provides more than just

equipment reliability; it also helps to save energy, extend equipment

life, reduce system downtime and increase the overall safety of the facility.

Labels:

#Avantis,

Avantis EAM,

Condition Based Maintenance,

EAM,

sustainability

Friday, January 17, 2014

MES for Metals & Mining

Customer Content verified by TechValidate.

Manufacturing Execution Systems--they are not just for food and beverage manufacturers! Here is an example of a Wonderware MES customer using the same framework and product features for a metals/mining application. Foremost for M3 (Metals, Mining, Minerals) companies are productivity (ie, avoiding equipment downtime), product quality, and labor management. Understanding the real-time performance of operations--well that's key to an optimized process. This specific customer example used Wonderware MES to help with not only downtime, but inventory management (what's been processed, what stage is the material in), equipment management, integration to automation/SCADA, and of course, reporting.

Making operations more productive, profitable, safe and predictable--it's the cornerstone for any MES implementation.

Thursday, January 16, 2014

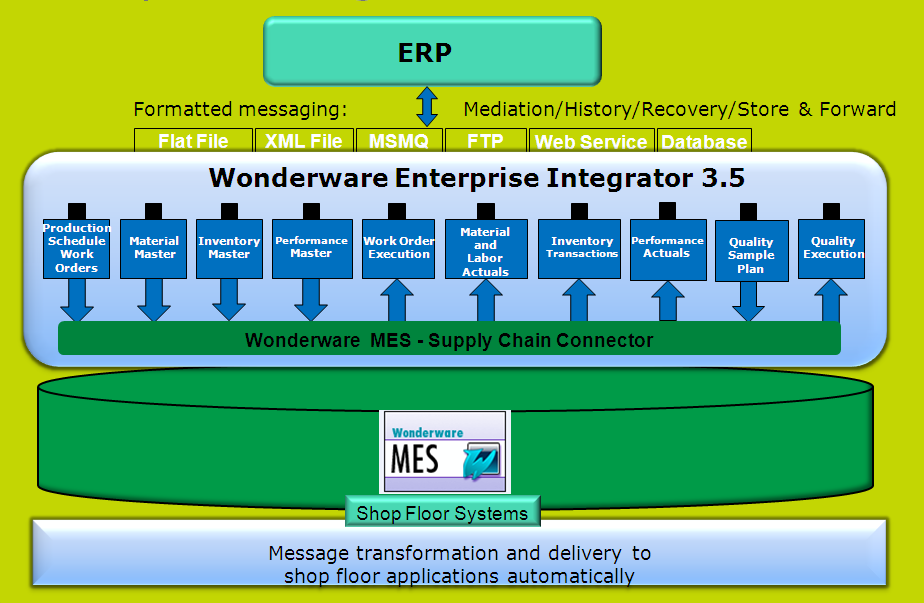

How Enterprise Integration Brings Enterprise Intelligence

For nearly 20 years, the "holy grail" of automation was to ensure effective communications between Level 0 and 1 (the automation/devices layer) with Level 2 and 3 (the visualization and Manufacturing Execution Layers). Why? Because in order to run a manufacturing enterprise effectively, you needed to not only understand, but bring the real-time process data into your business systems, for better, more informed decision making and overall analysis of yields, quality, throughput, inventory consumption, downtime, etc.

Enterprise Integration--the act of physically and logically "connecting the dots" between the process and the business systems--accomplishes a very important task, providing the data that drives the decisions. But there's another, sometimes nuanced, benefit of Enterprise Integration, and that's gaining Enteprise Intelligence.

Enterprise Integration--the act of physically and logically "connecting the dots" between the process and the business systems--accomplishes a very important task, providing the data that drives the decisions. But there's another, sometimes nuanced, benefit of Enterprise Integration, and that's gaining Enteprise Intelligence.

Wednesday, January 15, 2014

Fun with #Wordle: #Corporate Energy Management

If you need to understand the energy demands of your organization, and would like to see real-time energy consumption from the meter, consider Wonderware Corporate Energy Management software.

Tuesday, January 14, 2014

Large Enterprise Chemicals Company improves Quality and Productivity by more than 30% using Wonderware MES!

Customer Proof verified by TechValidate.

Wonder why you should consider a #ManufacturingExecutionSystem? Here's a proof point for you. A large chemicals customer was able to increase their overall product quality, and operations productivity, using Wonderware MES Solutions.

MES software has been used for over 25 years to manage the transformation of raw materials through finished goods for a variety of industries and customers. Especially in this day of strict controls and regulations, having an MES provides a solid infrastructure for process control and Good Manufacturing Practices. Organizations like MESA International have focused on bringing end users, solution providers and vendors together to benefit and progress the industry.

But the proof is in the actual benefits, and here's a customer example of the value they've received by implementing an MES system from Wonderware.

Repost, with comments: 2014 Manufacturing Trends Survey: The Swagger’s Back

2014 Manufacturing Trends Survey: The Swagger’s Back

Great news from the food and beverage industry, courtesy of Food Processing. Renewed vigor in investments, training, and confidence bodes well for us that serve this industry, and in the report you can see that priorities include food safety, quality initiatives, and automation.

Invensys is a long-time supplier to the food and beverage industry, meeting their needs for productivity, visibility, knowledge management. This is an industry driven by consumer behavior, and innovation is constant, be it packaging improvements, distribution methods, or revising recipes to reflect changing consumer tastes. Products such as MES, Batch and Workflow enable these manufacturers to standardize practices, proliferate changes, and maintain validated and certified operations.

So as food and beverage manufacturers progress, expand operations, and enforce continuous improvement of products and operations, we in the automation industry applaud, and support your efforts.

Monday, January 13, 2014

Fun with #Wordle: #Wonderware Historian.

http://global.wonderware.com/EN/Pages/WonderwareHistorian.aspx

Need a real-time database to manage the thousands of points of data that your process generates? With the rigor and capacity to manage large, distributed enterprises, Wonderware Historian meets the needs of a single plant, through multi-site, global data acquisition, storage and reporting. An #InTouch user? Consider Wonderware Historian to add a level of detail and relevancy to your visualization.

New-generation automation software for smartphones and tablets | Automation World

New-generation automation software for smartphones and tablets | Automation World

A good article from @AutomationWorld on the next-generation of reporting and analysis products built on cloud and mobile technologies. These meet the needs of users for on-demand, relevant insight into their operations, in real-time. It makes big data a big deal!

A good article from @AutomationWorld on the next-generation of reporting and analysis products built on cloud and mobile technologies. These meet the needs of users for on-demand, relevant insight into their operations, in real-time. It makes big data a big deal!

Sunday, January 12, 2014

Fun with Wordle: #Wonderware MES

Wordle (www.wordle.net) is a fun program to creatively depict words as pictures. Here's our rendition of what Wonderware MES Solutions customer benefits would look like. I think it makes a point: the speed, customer satisfaction, and operations improvement are obvious!

Saturday, January 11, 2014

Repost, with comments: New Whitepaper on Survey Data: Less Ugly, More Understandable

http://www.tableausoftware.com/about/blog/2014/1/new-whitepaper-survey-data-less-ugly-more-understandable-27812

It's been no secret that for over 4 years, Wonderware has been a close partner of Tableau Software, using its award-winning Business Intelligence tool for our own visualization and dashboarding of Wonderware Intelligence Enterprise Manufacturing Intelligence software. Using best-of-breed Tableau, we offer customers flexibility, market-leading performance, and deep domain experience for effectively building and displaying information-rich, intuitive charts and graphs that reflect the real-time industrial process.

Tableau just released a good white paper on making your data beautiful...I've included the link and believe it's worth your time to read, and learn from a leader.

|

| Wonderware Intelligence uses Tableau for dashboard & visualization for operational intelligence |

Tableau just released a good white paper on making your data beautiful...I've included the link and believe it's worth your time to read, and learn from a leader.

Friday, January 10, 2014

Repost, with comments: Big Data Strategy: s+b’s Strategy of the Year

http://www.strategy-business.com/blog/Big-Data-Strategy-sbs-Strategy-of-the-Year

Big data has become part of the "triliogy" of new initiatives for businesses--along with the cloud and mobile, really transforming the way companies are doing business and interacting with systems, people and equipment.

This post from Strategy & Business discusses the value & initiatives that a company should consider for using and leveraging a big data strategy.

At Wonderware, we've supported manufacturing "big data" for many years, whether it's for real-time series process analysis (Historian, Historian Client), or for manufacturing intelligence (Wonderware Intelligence) where multiple databases can be accessed, the data related in context to one another, and then presented in a graphically rich dashboard.

The point is that depending upon a user's needs, these different "industrial big data" products can help them make more sense of the data that's within their plant or enterprise--providing relationships to events, allowing for better drill down and analysis. If you have a data historian, and aren't using one of these analytical products, you may be missing important aspects of your process that you could easily improve, or gain better insight into.

Big data has become part of the "triliogy" of new initiatives for businesses--along with the cloud and mobile, really transforming the way companies are doing business and interacting with systems, people and equipment.

This post from Strategy & Business discusses the value & initiatives that a company should consider for using and leveraging a big data strategy.

At Wonderware, we've supported manufacturing "big data" for many years, whether it's for real-time series process analysis (Historian, Historian Client), or for manufacturing intelligence (Wonderware Intelligence) where multiple databases can be accessed, the data related in context to one another, and then presented in a graphically rich dashboard.

The point is that depending upon a user's needs, these different "industrial big data" products can help them make more sense of the data that's within their plant or enterprise--providing relationships to events, allowing for better drill down and analysis. If you have a data historian, and aren't using one of these analytical products, you may be missing important aspects of your process that you could easily improve, or gain better insight into.

Thursday, January 9, 2014

Repost, with comments: Intel Axes McAfee Security Brand, Repositions as Key Mobile Player

http://thevarguy.com/network-security-and-data-protection-software-solutions/intel-axes-mcafee-security-brand-repositions?utm_source=feedburner&utm_medium=TVG&utm_campaign=NL&cl=article_3_b%3Futm_source%3D010914

This is an interesting article for a few reasons. Not only is Intel planning to disassociate itself from the McAfee branding, but their play into the "internet of things" can theoretically shake up the industry, providing many more opportunities for connectivity of, well, everything through their Edison chip.

Connecting people and technology is not new for industrial automation, at least within the confines of the plant and enterprise. What IS new is the extension outside of our domain, to the "real world" which provides additional context to the events. It's all about being smarter and more informed. This looks like a very interesting year ahead of us for progress.

This is an interesting article for a few reasons. Not only is Intel planning to disassociate itself from the McAfee branding, but their play into the "internet of things" can theoretically shake up the industry, providing many more opportunities for connectivity of, well, everything through their Edison chip.

Connecting people and technology is not new for industrial automation, at least within the confines of the plant and enterprise. What IS new is the extension outside of our domain, to the "real world" which provides additional context to the events. It's all about being smarter and more informed. This looks like a very interesting year ahead of us for progress.

Thank you, Automation Industry, for 30 years of employment

I gasp as I write this, but it's been 30 years since I was first employed by the automation industry. I started out selling photoelectric controls (you know, same technology as garage door openers, with a light beam that you break, sending out an electrical signal) and from there progressing to vision and barcode systems, industrial controls, and finally, and thankfully, software.

Wednesday, January 8, 2014

The intersection of food, and drugs

I read an article today about Nestle developing foods with "real" health benefits: Nestle to test effect of nutrients on human cells. At first glance, the title infers to activities that are scary, ominous. But further reading, you find that Nestle is developing foods that are good for you--provide health benefits beyond nutrition.

This is interesting for a number of reasons

Tuesday, January 7, 2014

Cloud Deployments Grow with Utilities

One industry segment that has embraced the concept of “iPhone as HMI” is municipal water and wastewater utilities. With widely distributed wells, pumping stations, valves, treatment facilities, and many miles of pipelines, the ability to use the cloud to monitor and control equipment is very appealing.

James Jacklett, electrical and signal supervisor for Carson City (Nev.) Public Works, says that the city has deployed a two-sided system on the cloud to support both management and operators as they keep water and wastewater flowing throughout the city and surrounding areas. Operators use Wonderware InTouch to access control systems and individual tags as needed, while managers use SmartGlance to keep tabs on production levels and work orders.

Jacklett explains, “In the past, our management team would have to log in through remote access through the VPN and then log into the Wonderware application, or be on our intranet here to get to the server. With our new system I’m able to deliver key performance indicators and critical process information such as production and demand on the water side, with ease of access wherever they are. They can be on the road or at a meeting, they can open their phone or iPad, get their information in a hurry, and contact someone if they see something they don’t like.”

Know More

James Jacklett, electrical and signal supervisor for Carson City (Nev.) Public Works, says that the city has deployed a two-sided system on the cloud to support both management and operators as they keep water and wastewater flowing throughout the city and surrounding areas. Operators use Wonderware InTouch to access control systems and individual tags as needed, while managers use SmartGlance to keep tabs on production levels and work orders.

Jacklett explains, “In the past, our management team would have to log in through remote access through the VPN and then log into the Wonderware application, or be on our intranet here to get to the server. With our new system I’m able to deliver key performance indicators and critical process information such as production and demand on the water side, with ease of access wherever they are. They can be on the road or at a meeting, they can open their phone or iPad, get their information in a hurry, and contact someone if they see something they don’t like.”

Know More

Subscribe to:

Comments (Atom)